Battery cabinet production and processing process

Welcome to our dedicated page for Battery cabinet production and processing process! Here, we have carefully selected a range of videos and relevant information about Battery cabinet production and processing process, tailored to meet your interests and needs. Our services include high-quality Battery cabinet production and processing process-related products and solutions, designed to serve a global audience across diverse regions.

We proudly serve a global community of customers, with a strong presence in over 20 countries worldwide—including but not limited to the United States, Canada, Mexico, Brazil, the United Kingdom, France, Germany, Italy, Spain, the Netherlands, Australia, India, Japan, South Korea, China, Russia, South Africa, Egypt, Turkey, and Saudi Arabia.

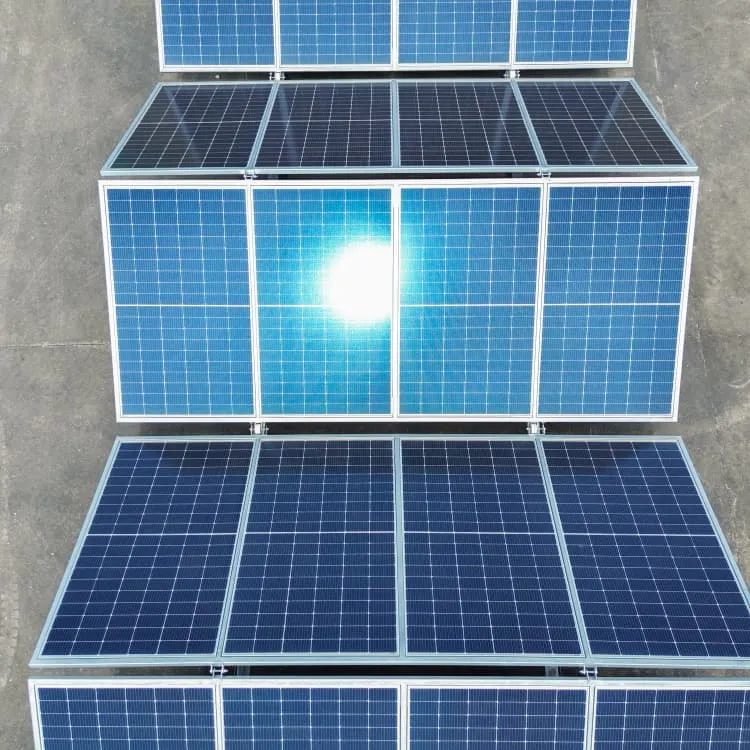

Wherever you are, we're here to provide you with reliable content and services related to Battery cabinet production and processing process, including cutting-edge solar energy storage systems, advanced lithium-ion batteries, and tailored solar-plus-storage solutions for a variety of industries. Whether you're looking for large-scale industrial solar storage or residential energy solutions, we have a solution for every need. Explore and discover what we have to offer!

Lithium battery energy storage cabinet processing factory

What are the benefits of lithium ion battery manufacturing? The benefit of the process is that typical lithium-ion battery manufacturing speed (target: 80 m/min) can be achieved, and the

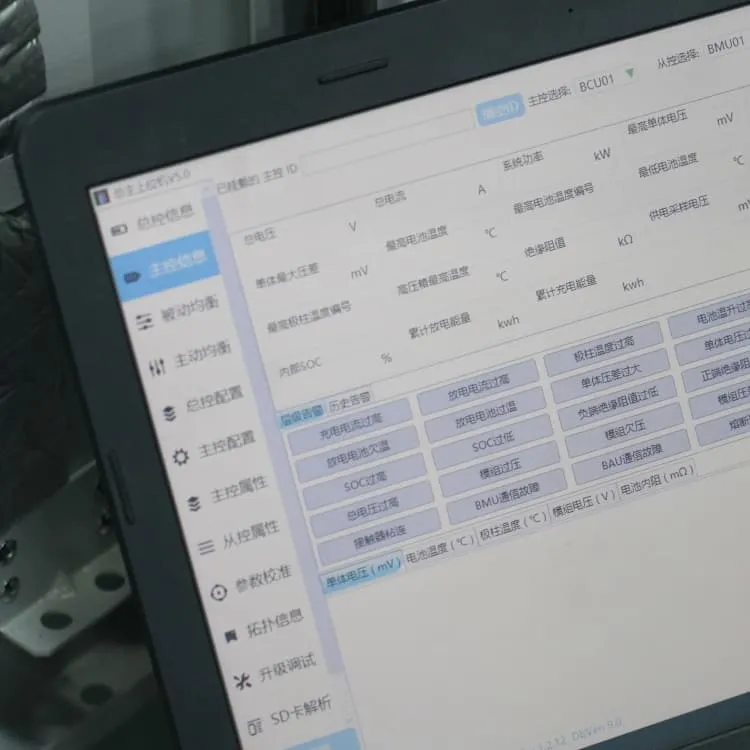

Illustrated explanation of the battery cabinet production process

The battery manufacturing process is a complex sequence of steps transforming raw materials into functional, reliable energy storage units. This guide covers the entire process, from

How Are Lithium Batteries Manufactured? A Step-by-Step

How are lithium batteries made step by step? Lithium batteries are manufactured through a multi-stage process: raw material preparation, electrode production, cell assembly, electrolyte

From Raw Materials to Reliable Power: Inside the Energy Storage

Ever wondered what goes into creating those sleek battery cabinets powering solar farms or backup systems? The energy storage equipment production process is like baking a multilayer

Illustrated explanation of the battery cabinet production process

The total cost of a lithium-ion battery can be divided into roughly 75 % material costs and 25 % production costs. [5, 6] To facilitate meaningful innovations in battery production, a thorough

FAQs 6

What is the battery manufacturing process?

The battery manufacturing process is a complex sequence of steps transforming raw materials into functional, reliable energy storage units. This guide covers the entire process, from material selection to the final product’s assembly and testing.

How a battery is assembled?

Battery module and pack assembly Individual cells are then grouped into modules and assembled into battery packs. This step involves: Module Assembly: Cells are connected in series or parallel configurations to achieve the desired voltage and capacity.

What is a battery formation process?

The formation process involves the battery’s initial charging and discharging cycles. This step helps form the solid electrolyte interphase (SEI) layer, which is crucial for battery stability and longevity. During formation, carefully monitor the battery’s electrochemical properties to meet the required specifications. 6.2 Conditioning

What are the stages of battery manufacturing?

The first stage in battery manufacturing is the fabrication of positive and negative electrodes. The main processes involved are: mixing, coating, calendering, slitting, electrode making (including die cutting and tab welding). The equipment used in this stage are: mixer, coating machine, roller press, slitting machine, electrode making machine.

What are the raw materials for battery production?

The raw materials for battery production, including lithium-ion battery manufacturing, are critical for ensuring high-quality output. The foundation of any battery is its raw materials. These materials’ quality and properties significantly impact the final product’s performance and longevity. Typical raw materials include:

How are lithium-ion batteries made?

The industrial production of lithium-ion batteries usually involves 50+ individual processes. These processes can be split into three stages: electrode manufacturing, cell fabrication, formation and integration. Equipment plays a critical role in determining the performance and cost of lithium-ion batteries.

Random Links

- Lebanon Photovoltaic Module Industrial Park Project

- Home inverter production

- How much power does a 1gw inverter have

- Is the energy storage equipment installed well

- What are the types of small-capacity energy storage batteries

- Communication base station solar energy manufacturers

- Australia Household Solar Photovoltaic Power Generation System Project

- Photovoltaic solar panel prices in Canada

- Five major systems composed of battery cabinets

- Inverter to 12 volts

- New generation of communication base station wind and solar complementary equipment

- Tajikistan monocrystalline silicon photovoltaic panel charging

- Telecom site lithium battery pack 12v battery cabinet

- North Korea photovoltaic inverter grid-connected voltage

- Lebanese liquid cooling energy storage container manufacturer

- Middle East Wind and Solar Energy Storage Station Power Generation Prices

- Modern energy storage battery cabinet photovoltaic supplier

- Which site cabinets are included in the energy storage battery cabinet

- Ireland Off-Grid Solar Power System

- 12v-90v to 220v inverter

- AC charging pile plus energy storage cabinet

- Comprehensive introduction to energy storage equipment

- Photovoltaic inverter sine

- Moldova office building photovoltaic curtain wall brand

- Maximum operating voltage of photovoltaic panels

- BESS a large mobile energy storage vehicle company in the Solomon Islands

- Swaziland lithium battery cabinet manufacturer

- How much does it cost to customize an outdoor communication battery cabinet in the Central African Republic

- How much does a 100KW power storage cabinet cost

- Equatorial Guinea lithium iron phosphate energy storage equipment