Uganda lithium iron phosphate battery pack processing

Welcome to our dedicated page for Uganda lithium iron phosphate battery pack processing! Here, we have carefully selected a range of videos and relevant information about Uganda lithium iron phosphate battery pack processing, tailored to meet your interests and needs. Our services include high-quality Uganda lithium iron phosphate battery pack processing-related products and solutions, designed to serve a global audience across diverse regions.

We proudly serve a global community of customers, with a strong presence in over 20 countries worldwide—including but not limited to the United States, Canada, Mexico, Brazil, the United Kingdom, France, Germany, Italy, Spain, the Netherlands, Australia, India, Japan, South Korea, China, Russia, South Africa, Egypt, Turkey, and Saudi Arabia.

Wherever you are, we're here to provide you with reliable content and services related to Uganda lithium iron phosphate battery pack processing, including cutting-edge solar energy storage systems, advanced lithium-ion batteries, and tailored solar-plus-storage solutions for a variety of industries. Whether you're looking for large-scale industrial solar storage or residential energy solutions, we have a solution for every need. Explore and discover what we have to offer!

Top Lithium Ferro Phosphate Battery Manufacturers Suppliers in

Lithium Ferro Phosphate batteries are environmentally friendly and help to reduce the carbon footprint of the population. From Solar power storage to EVs, the Lithium Ferro battery market

Top Lithium Ferro Phosphate Battery Manufacturers Suppliers in Uganda

Lithium Ferro Phosphate batteries are environmentally friendly and help to reduce the carbon footprint of the population. From Solar power storage to EVs, the Lithium Ferro battery market

Lithium Iron Phosphate/ Gel Battery – Enagyl Limited – Uganda

These Lithium Iron Phosphate batteries provide long-lasting energy storage for solar power systems. They support multiple parallel connections, are compatible with various inverters,

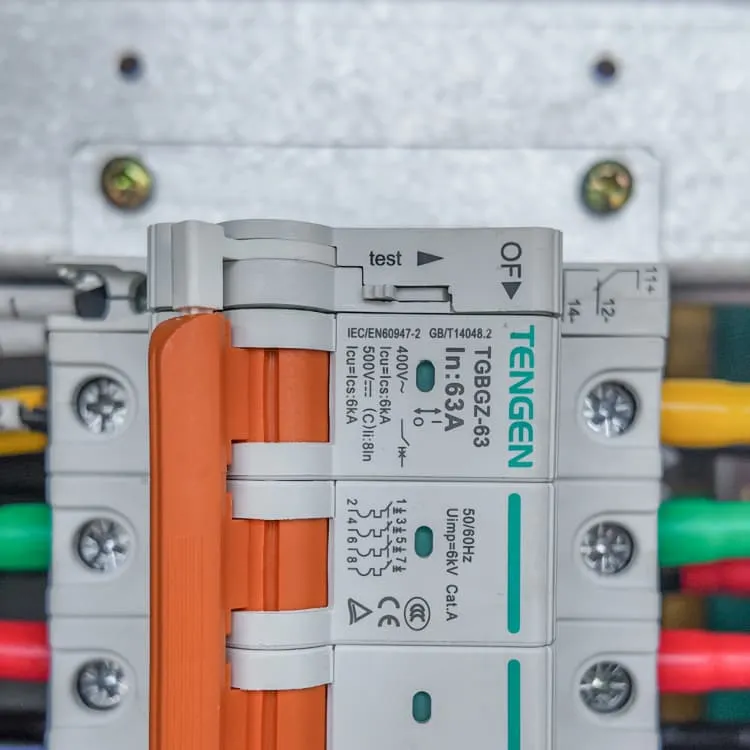

Industrial preparation method of lithium iron phosphate (LFP)

This year''s particularly hot BYD blade battery is the lithium iron phosphate battery. The basic production process of lithium iron phosphate mainly includes the production of iron phosphate

FAQs 6

What is the production process of lithium iron phosphate (LFP) batteries?

The production procedure of Lithium Iron Phosphate (LFP) batteries involves a number of precise actions, each essential to guaranteeing the battery’s efficiency, security, and long life. The procedure can be broadly divided into material prep work, electrode fabrication, cell setting up, electrolyte filling, and development biking.

Should lithium iron phosphate batteries be recycled?

However, the thriving state of the lithium iron phosphate battery sector suggests that a significant influx of decommissioned lithium iron phosphate batteries is imminent. The recycling of these batteries not only mitigates diverse environmental risks but also decreases manufacturing expenses and fosters economic gains.

Why is quality control important for lithium iron phosphate (LFP) batteries?

Quality control and testing are essential components in the manufacturing procedure of Lithium Iron Phosphate (LFP) batteries. Provided the high demand for reliability and performance, it is imperative to ensure that every stage of production meets rigorous quality standards.

Can lithium iron phosphate positive electrodes be recycled?

Traditional recycling methods, like hydrometallurgy and pyrometallurgy, are complex and energy-intensive, resulting in high costs. To address these challenges, this study introduces a novel low-temperature liquid-phase method for regenerating lithium iron phosphate positive electrode materials.

What is the production process of lithium iron phosphate?

The basic production process of lithium iron phosphate mainly includes the production of iron phosphate precursor, wet ball milling, spray drying, and sintering. There are also many studies on the synthesis process of lithium iron phosphate, and how to choose the process method is also a subject.

What is a lithium phosphate (LFP) battery?

This material enables reliable cost and discharge cycles, adding to the total performance of the battery. The electrolyte in LFP batteries is normally a lithium salt, such as lithium hexafluorophosphate (LiPF 6), liquified in a combination of organic solvents like ethylene carbonate (EC) and dimethyl carbonate (DMC).

Random Links

- Energy storage cabinet batteries are station cabinets

- China s pressure-type solar energy storage cabinets

- Hybrid compression energy storage and conversion device

- Latest battery cabinet manufacturer in Poland

- Battery energy storage power station energy storage method

- Belgian energy storage container

- Price of self-use energy storage power station

- Tajikistan Hybrid Compression Energy Storage Project

- Brazil PV Energy Storage 100kw Inverter

- Guatemala solar base station costs

- Photovoltaic power station in the Bahamas

- Laos photovoltaic energy storage lithium battery manufacturer

- Chuguang brand pure sine wave inverter

- How much does a Montenegro energy storage system typically cost

- New photovoltaic module exports

- Vietnam Power Plant Energy Storage Group

- Can solar outdoor power supply be used

- Energy storage cabinet batteries discovered in Latvia

- Small Business Energy Storage Products

- 110V inverter to 220V

- Rooftop terrace solar integrated machine for home use

- Türkiye lithium battery pack customization

- Battery voltage of Sierra Leone communication base station

- West Asia sells solar energy storage cabinets

- Monocrystalline silicon 400w photovoltaic panel

- 400W Solar System

- Plateau Communication Base Station Energy Storage System

- Solar power generation folding photovoltaic panels

- Cost-effective outdoor power supply within 1 000 US dollars

- Old base station power supply