Energy storage container water cooling design

Welcome to our dedicated page for Energy storage container water cooling design! Here, we have carefully selected a range of videos and relevant information about Energy storage container water cooling design, tailored to meet your interests and needs. Our services include high-quality Energy storage container water cooling design-related products and solutions, designed to serve a global audience across diverse regions.

We proudly serve a global community of customers, with a strong presence in over 20 countries worldwide—including but not limited to the United States, Canada, Mexico, Brazil, the United Kingdom, France, Germany, Italy, Spain, the Netherlands, Australia, India, Japan, South Korea, China, Russia, South Africa, Egypt, Turkey, and Saudi Arabia.

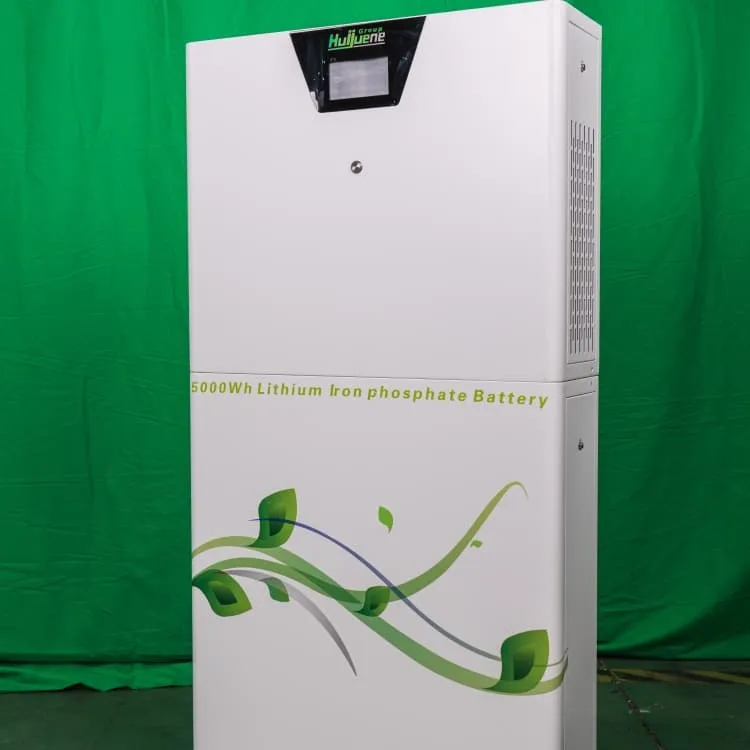

Wherever you are, we're here to provide you with reliable content and services related to Energy storage container water cooling design, including cutting-edge solar energy storage systems, advanced lithium-ion batteries, and tailored solar-plus-storage solutions for a variety of industries. Whether you're looking for large-scale industrial solar storage or residential energy solutions, we have a solution for every need. Explore and discover what we have to offer!

Study on uniform distribution of liquid cooling pipeline in container

Designing a liquid cooling system for a container battery energy storage system (BESS) is vital for maximizing capacity, prolonging the system''s lifespan, and improving its

Important factors to consider in energy storage system design

BESS consists mainly of shipping containers and step-up transformers, and the different systems all look very similar on the surface. Careful consideration of the differences ensures that BESS

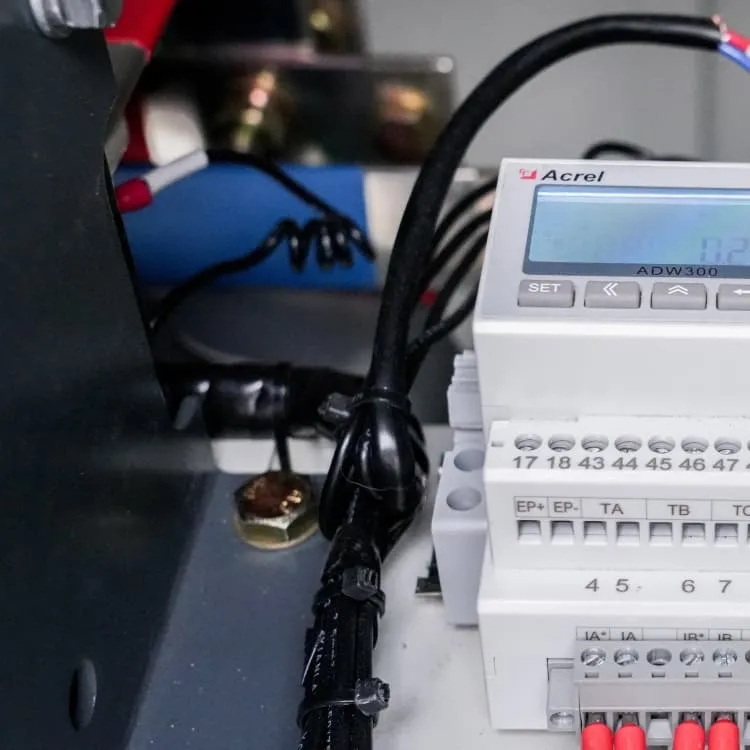

Liquid Cooling System Design, Calculation, and Testing for Energy

Explore the application of liquid cooling in energy storage systems, focusing on LiFePO4 batteries, custom heat sink design, thermal management, fire suppression, and testing validation

Liquid-Cooled Energy Storage System Architecture and BMS Design

The liquid-cooled energy storage system integrates the energy storage converter, high-voltage control box, water cooling system, fire safety system, and 8 liquid-cooled battery packs into

FAQs 6

Which cooling system is a good application for thermal ice storage?

Any chilled water cooling system may be a good application for thermal ice storage. The system operation and components are similar to a conventional chilled water system. The main difference is that thermal ice storage systems are designed with the ability to manage energy use based on the time-of-day rather than the cooling requirements.

What construction materials are used for ice storage containers?

Common construction materials are reinforced concrete and steel. Location: Ice storage containers may be located totally below grade, partially buried or completely above grade. They can be designed as an integral part of the cooling plant or placed in a remote location.

What is a glycol fluid / chilled water heat exchanger?

A glycol fluid / chilled water heat exchanger will be used to separate the glycol and chilled water loops. The system will be a partial ice storage system. The design day cooling load profile has a cooling peak of 10.500 kW and a night cooling load of 11,000 kW to 1800 kW.

Why should civil and structural engineers be involved in storage container design?

Civil and structural engineers should be involved in all storage container locations and designs. Waterproofing is an important part of the storage container design. All construction joints and pipe penetrations must be sealed to withstand the hydraulic pressure of the water. While steel surfaces are waterproof, concrete surfaces may be porous.

What is thermal energy storage?

Thermal Energy Storage (TES) is the term used to refer to energy storage that is based on a change in temperature. TES can be hot water or cold water storage where conventional energies, such as natural gas, oil, electricity, etc. are used (when the demand for these energies is low) to either heat or cool the storage water.

What is a distribution cooling pipe?

The distribution cooling pipes are typically sized for a delta-T of 20°F (11.1°C). This reduces the chilled water flow volume, thus enabling the use of smaller pipes and pumps. The ice storage provides the energy management ability to shift energy use to lower cost periods of time.

Random Links

- Tender for photovoltaic solar power project for communication base stations

- Haiti Photovoltaic Power Generation and Energy Storage Operation Company

- What s inside the inverter cabinet

- How much is the lithium battery for a bms system

- Huawei Central Asia double-glass photovoltaic modules

- Brunei energy storage power station planning latest

- Libya off-grid integrated photovoltaic energy storage cabinet

- What is the size of the photovoltaic energy storage system

- The role of the booster station energy storage system

- Which photovoltaic water pump inverter is best

- High-voltage direct-mounted energy storage system

- Georgia PV Energy Storage 100kw Inverter

- Huawei photovoltaic panel assembly price

- Russian outdoor base station integrated cabinet

- Southern Europe Home Solar All-in-One

- Containerized special rechargeable battery price

- New way of flywheel energy storage

- Advantages and disadvantages of high-power external energy storage batteries

- Direct installation of photovoltaic panels on the roof

- How much electricity can the energy storage battery generate

- Solar system slowdown

- Energy storage battery manufacturing in Uzbekistan

- 445w photovoltaic panel series voltage

- Base station solar panel connection

- Price of sine wave inverter in China and Africa

- Can a 60V inverter be used with a 48V one

- Industrial photovoltaic panels wholesale factory direct sales

- Benefits of Algerian energy storage power station

- Bahrain phase change energy storage system manufacturer

- Pack batteries